D571: CNC for Synchronous Running Cutting-To-Length Devices (Flying Saws)

The CNC D571 is based on the CompactPCI system D500, and the operating station E3000. It is used as control system for synchronous running cutting-to-length devices (Flying Saws) for example in tube welding lines. The D571 controls the motion of a synchronous running cutting-to-length device (saw carriage and saw stroke) for exact partitioning of endless manufactured material, and offers functionality to automate and control additional linked processes.

The CNC D571 is available in a configuration that can be used as replacement for older OPTRONIC control systems for synchronous running cutting (D115, D141, D151, D171).

Functions of the CNC D571

- Closed loop position and speed control for the saw carriage to enable position and speed synchronous driving with the cut-off point.

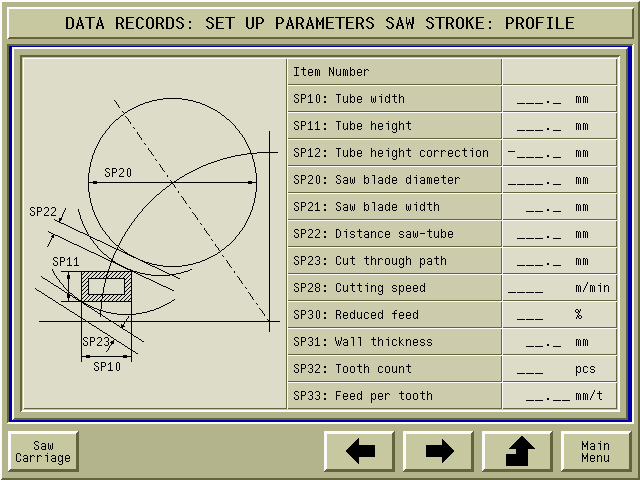

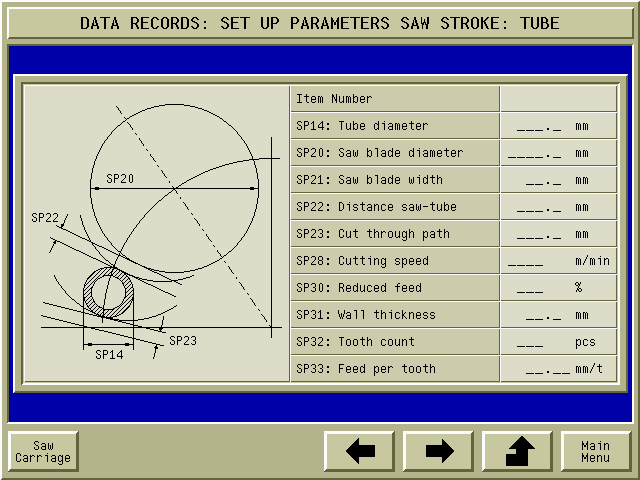

- Closed loop position and speed control for the saw stroke with programming of the upper and lower position for the cut, by use of the geometry (saw blade diameter and material cross section) or teach-in.

- Adaptive control of the motion-sequences in order to prevent the drives from damage and to optimize the cycle time.

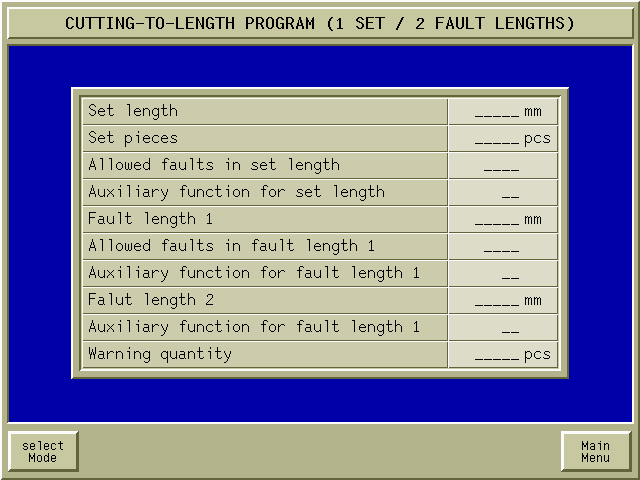

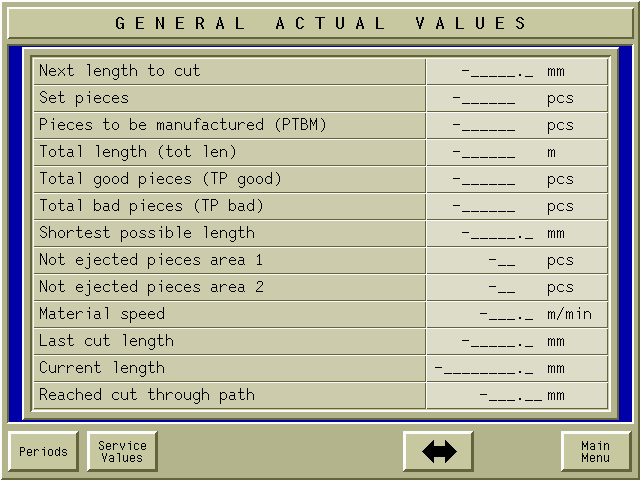

- Fault detection, fault tracking, and position accurate fault marking. Sorting out of faulty pieces by use of various fault criteria.

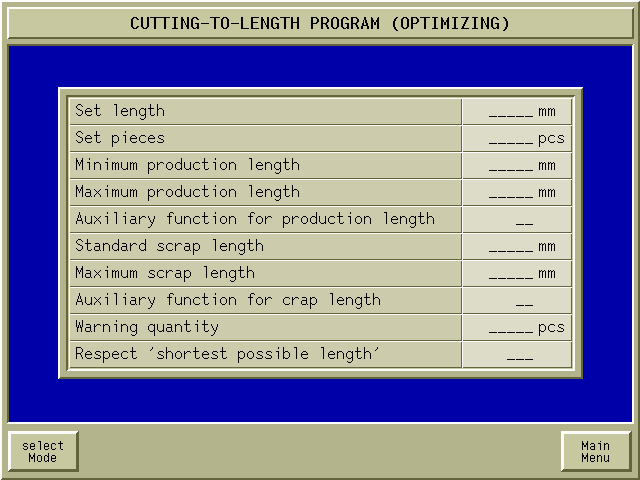

- Residual length optimization and scrap minimization.

- Digital and analog outputs used as subsidiary signals for plant control.

- Programming of the lengths and quantities to be manufactured.

- Communication with PLC over PROFIBUS DP, or by use of electrically isolated digital inputs and outputs.

- User-friendly operation, powerful visualization software.

- Testing mode with simulation of control system external components (PLC, drives, etc.) for commissioning support and problem analysis.

- Simulation of the production (virtual run of the production process) to determine cycle times, to optimize parameter settings, and to test alternative production data. The simulation can be executed while running normal production.

- TCP/IP networking. Data exchange with Windows and Linux computers by use of the protocols FTP, SMB, and NFS.

- Optionally with data base to store process data.

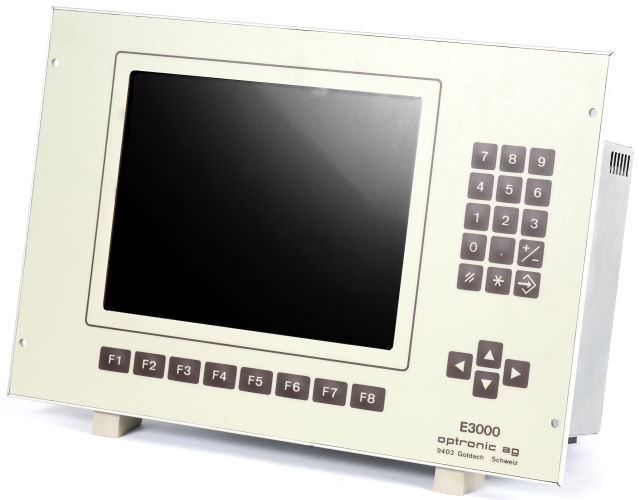

Operating Station E3000 to CNC D571

The D571 is completely parameterized by use of the operating station E3000. The E3000 also serves to backup and restore machine constants and data sets. The user interface is implemented as simple as possible, so that it is easy to use by the operator. The E3000 is equipped with eight softkeys, four cursor keys, and a numeric key pad.

OAGLinux is used as operating system.